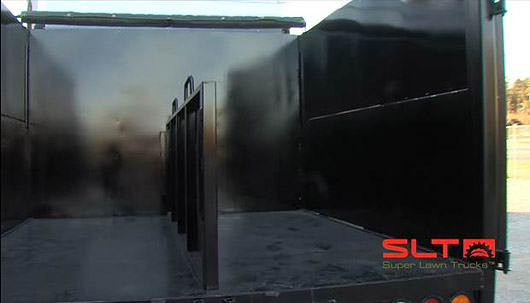

The 60” dump sides option lets you load the truck high with debris or lighter materials. Remove the top 30” panel and fold down the lower panel to allow a forklift to load palletized materials from the side. Swinging rear doors (in place of a tailgate) make it just as easy to load from the back. These features also provide easy access for hand-loading materials.

Making your trucks more efficient

By Tom HatlenIf you’ve ever thought about making your trucks/trailers more efficient, Tony Bass is a good person to talk to. Tony started out as a landscape contractor in 1983 – but with an Agricultural Engineering degree. His company became his truck testing ground. With a head for efficiency and business he became a Vander Kooi Consultant in 1998 helping other contractors.

That same year, he launched Super Lawn Technologies, offering his truck designs to other contractors. He sold his contracting company in 2006, and now devotes all his time to advising contractors and to improving truck designs.

The truth about trailers & trucks

Early on, Tony came to understand that trailers were a problem to be avoided whenever possible. When you add a trailer you’re adding parts that can breakdown. Trailers are awkward to maneuver, park and back. They slow you down and cause accidents. There’s even a website called DangerousTrailers.org. Driving extra trucks/vehicles to a job site is also inefficient and expensive.To eliminate extra trucks and trailers, Tony created a hybrid dump/box truck for landscape and hardscape contractors. The Super Contractor Truck combines the walk-in tool storage of an enclosed truck body with a dump truck capable of hauling palletized materials, bulk materials and everything else.

Over the past 30+ years Tony’s truck testing ground expanded from his own company to other contracting companies all over the U.S. and Canada. As contractors of all different sizes with different business mixes ask for different things, the number of options grew. Today, Tony says that when a contractor asks him for something, there’s a good chance he’s built it before.

“We’ll ask for a tool list for your crew. I helped a contractor design a truck the other day. When he gets his truck he will have inside tool storage up on the sidewall for the 19 shovels, rakes, hand brooms and so forth. He's got storage for his water cooler. He's got built-in toolboxes for his drills, saws and small power tools.”

“We want each and every tool that goes on the truck to have a specific storage plan. It’s not in a pile on the floor. Everything has its own place. That way, daily inventory of tools happens with a 10 second visual inspection, and everything the crew needs is stored safely. It’s stored securely, and it’s right there where they can find it every day on every job site.”

The Super Lawn Technologies staff talks thru every part of the truck – the dump body options, the cab choices, exterior options – the same way. Tony explains, “I can’t stress enough how important these things are to productivity.”

To learn more about Super Contractor Trucks, call (866) 923-0027 or visit SuperContractorTrucks.com

Onboard gas tanks have been a winner since Tony introduced his first truck in 1988. Having tanks onboard keeps crews productive on the work site and out of the convenience store. No dirty gas cans piled around.

Tony says onboard power inverters and compressors are probably the fastest-growing options contractors are adding. As such, the company developed a Power Tool Configuration with a built-in DC powered air compressor (not pictured) along with a 1500 watt power inverter. This lets you run air tools and keep battery tools charged. And, yes, that is a microwave running off the inverter.

A dump divider option allows crews to dump debris piled on one side while storing materials like mulch on the other side. Just swing open the back door on the debris side when you’re ready to dump it. Tony says the doors are built solid with a secure latching system to hold up strong and keep materials in place.

|  |

The Super Contractor Truck offers 2 options for side ramps off the tool shed: A hydraulic ramp (SR 3200) and a fold-down ramp (MR 750). The hydraulic ramp holds up to 3,200 lbs allowing you to drive heavier equipment into the storage unit. The ramp also serves as a secure door on the storage unit. The fold-down ramp has a 750 lb capacity, fine for loading power wheelbarrows, compactors, etc. There are also ramp and step options for the dump body.