Contractor Stories

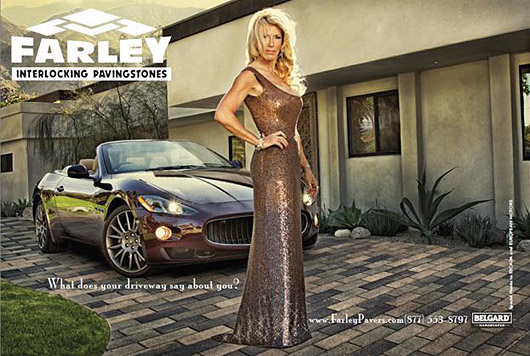

Ads for Farley Interlocking Paving impress those in the upscale marketplace that fashionable pavers are part of the high life. Charissa poses for many of her ads. "We brand with that lifestyle. There's a plank product in our newest ad to help educate the contemporary market that we have planks, and products geared toward them."

Are your designs falling from fashion?

Getting creative in paver design lets Farley Interlocking Paving appeal to more people in more markets.

By Tom HatlenFarley Interlocking Paving

Palm Desert, CACharissa Farley, President

Founded 1974 (Farley Tile)

Services

100% hardscape installation/ distribution/designBusiness mix

50% community remodels30% commercial/municipal

10% new custom homes

10% high-end housing tracts

Largest project

$2,500,000Annual sales

$2 - $5 million annuallyEmployees

15-60Charissa has positioned herself as the regional paver design expert. For starters, it's easier to be an expert when you focus 100% on pavers as she does. They don't install other outdoor room products. Charissa researches architectural styles, and she's traveled extensively focused on designs and trends. She's immersed herself in the area's fashion community, and views pavers from that aspect – just as her prime target audience (affluent 55+ women) does.

"Those who follow architectural trends may not just be looking for something that is old world European, Tuscan or Mediterranean. Mid-century modern and contemporary architecture is huge now, with big pieces, cleaner lines, textures and lighter colors. So we have to watch those trends, and we've got to have the products that address them.

"Many people only know the paver industry by products like the pillow-top rectangle & square in an I-pattern. You see it everywhere. So we lose some of our audience. They kind of turn up their nose and think pavers are old fashioned and dated.

"Just because something sold well 5 years ago, architectural fashion doesn't stay the same. You have to stay on the front end of fashion, not on the back end. What Beyonce is wearing now will be in Walmart 6 years from now. When it hits Walmart, you better be on the front end of something else."

Getting creative with local concrete

Charissa prides herself on offering the largest selection and the most up-to-date styles in her showroom collection of concrete pavers, clay brick and natural stone imported from around the world. "I have pavers from Europe, China, Mexico, Indonesia, Israel... I have brick from Georgia. I have slate pavers from the east coast. I have white cement pavers from Florida. I want design professionals to know that this is the only source where you can see everything side by side."She says they've installed a lot of expensive products, but in recent years they've created a unique niche by using locally produced concrete pavers more creatively. So they only look expensive. The idea was part of their plan to "think their way out of the recession."

Charissa negotiated with manufacturers to produce special color blends for her and to apply shot blast and grind textures to products. "They're just like me. They want to sell product. So they trusted me to come up with some ideas for products customers will want. We came up with 5 or 6 new product lines for them. And now everybody's getting on board because they're selling."

At the same time, Charissa says all the manufacturers have begun offering more contemporary products on their own. "I wake up happy everyday that I am in the paver industry because I have so much more to work with than any of the competing products like stamped or scored concrete. And we can compete in pricing."

Charissa says she negotiated with the manufacturer on the costs to lighten the color and to lightly shot blast these inexpensive pavers to create a highly-refined, expensive look.

This project uses a basic square paver turned upside down and textured. Charissa says, "There's a manufacturer here that can do different finishes. So I just took the most inexpensive paver I could find and had them do a hammer finish to the bottom side of it. That way I don't have a chamfer and it looks more like cut granite in a very inexpensive paver. People love it. It looks rich; it looks expensive; it looks like granite.

"That was one of our goals in the recession: What can we do that's special, unique and looks great for cheap."

"That was one of our goals in the recession: What can we do that's special, unique and looks great for cheap."

This is a newer concrete paver product available "off-the-shelf" from a Southern California manufacturer. Charissa says, "It's just a cool, non-tumbled product that's a little different than what we've had in the past. It's done in a face mix which gives it a little different texture on top. It's a nice in-between option if your property isn't old world and it isn't clean, crisp mid-century modern. It goes well in different architectural styles.

"Some other unique things about this product is that it is not a blend and it has a denser pigmentation on top. They're similar enough that I can mix them."

"Some other unique things about this product is that it is not a blend and it has a denser pigmentation on top. They're similar enough that I can mix them."

For this condo project, Charissa requested a grind finish for an inexpensive paver. The grind exposed the aggregate and provided the refined appearance she was looking for. "It's a product I use for mid-century modern or contemporary architecture.

"When you grind it, you're exposing the aggregate. The aggregate pops a dark gray, a light gray and a whitish beige. That's just the natural aggregate we use around here.

"You can mix special aggregates in your pavers. I put amber glass in the pavers for a multi-billionaire so the pavers sparkled in the sun. Very, very pretty. But that's more expensive."

"When you grind it, you're exposing the aggregate. The aggregate pops a dark gray, a light gray and a whitish beige. That's just the natural aggregate we use around here.

"You can mix special aggregates in your pavers. I put amber glass in the pavers for a multi-billionaire so the pavers sparkled in the sun. Very, very pretty. But that's more expensive."

Charissa says this installation was done for a very high-end property. "But it's a spec house. And everybody's gun shy right now watching their costs. So how can I make something look fantastic that's cheap, cheap, cheap?"

She used a standard 4" x 4" paver and simply installed it upside down in a stack bond with no special treatment of any kind. Keeping the lines straight was a challenge and added a little extra to the labor cost.

She says manufacturers often add ingredients like hardeners which settle down to the bottom of the paver. So the bottom looks a little mottled, a little blotchy. And, since the surface isn't chamfered or tumbled, the edges are going to chip.

"I want it to look mottled. I want it to look aged, because it's a very plain paver. You want the chipping and imperfections. We want this to look like Europe. You have to have a customer that knows that this isn't Disneyland.

"I was a little nervous on this one because I was going out on the edge a bit. But I'm thrilled with how that turned out. It almost gave a Moroccan vibe to this house."

She used a standard 4" x 4" paver and simply installed it upside down in a stack bond with no special treatment of any kind. Keeping the lines straight was a challenge and added a little extra to the labor cost.

She says manufacturers often add ingredients like hardeners which settle down to the bottom of the paver. So the bottom looks a little mottled, a little blotchy. And, since the surface isn't chamfered or tumbled, the edges are going to chip.

"I want it to look mottled. I want it to look aged, because it's a very plain paver. You want the chipping and imperfections. We want this to look like Europe. You have to have a customer that knows that this isn't Disneyland.

"I was a little nervous on this one because I was going out on the edge a bit. But I'm thrilled with how that turned out. It almost gave a Moroccan vibe to this house."

Charissa says this project shows one of the great new plank products manufacturers now offer – without the special order charges she faced in the past.

"Our industry has been selling these to architects. But now they're available to homeowners. These are very important because we really needed some products for the very contemporary projects like this mid-century modern hotel. These are the types of things we need to take parts of the market that don't think we offer anything for their contemporary projects."

Charissa offers one caveat: "Bigger units like planks are typically weaker under vehicular loads. Contractors need to verify the product's load bearing capacity with the manufacturer. Some planks cannot be used in vehicular applications."

"Our industry has been selling these to architects. But now they're available to homeowners. These are very important because we really needed some products for the very contemporary projects like this mid-century modern hotel. These are the types of things we need to take parts of the market that don't think we offer anything for their contemporary projects."

Charissa offers one caveat: "Bigger units like planks are typically weaker under vehicular loads. Contractors need to verify the product's load bearing capacity with the manufacturer. Some planks cannot be used in vehicular applications."

For the drive and surrounding area of this Moroccan-style house, Charissa resurrected an old school paver from the 1990s. "This is a paver that we would have stopped carrying because it's not fashionable enough. The architect wanted a Moroccan vibe, and I was thinking of Moroccan tile. So I found this shape, and we took a really wild color blend. There's peaches and greens in there. The house has green in the roof. It's something unique and interesting for a unique and interesting architectural style."

The project was done in 3 different standard 3-color blends. Charissa says the trick to mixing pavers is to use blends that share 1 or 2 colors. "If you mix solid colors, you get a very checkerboard effect, if that's what you want. In that project, I think I've got a tan/gray, a green/gray and a brown/gray. The shared gray visually blended the installation without a checkerboard effect."

The project was done in 3 different standard 3-color blends. Charissa says the trick to mixing pavers is to use blends that share 1 or 2 colors. "If you mix solid colors, you get a very checkerboard effect, if that's what you want. In that project, I think I've got a tan/gray, a green/gray and a brown/gray. The shared gray visually blended the installation without a checkerboard effect."

The colors and texture of these "Desert Aggregate" pavers were chosen to blend with the natural stone found in the area like those to the side of the drive. It's a non-tumbled, non-chamfered paver shot blasted to expose the natural aggregate from a local quarry.

Charissa says she chose the colors by comparing different paver color blends to the colors of rocks from the nearby mountains. "I laid them all out to see what was closest. Then we exposed the natural aggregate which comes out of our local earth.

"People tend to think of stone products from Indonesia as something that's earthy and real. And they think of concrete pavers as something fake and synthetic. So I explain to them that these products came from within 300 miles of your house. It's local dirt and it's local aggregate. It's very earthy and indigenous.

"It's a very European mentality when you look at these old French farmhouses, that the plaster came from the dirt surrounding their house. And the roof came from the clay. That's how I portray these concrete pavers as something very cool and crafted from local rock that will become a beautiful component of your house. This puts a new value on a product that's not terribly expensive."

The shot blast fee was about $1 per square foot.

Charissa says she chose the colors by comparing different paver color blends to the colors of rocks from the nearby mountains. "I laid them all out to see what was closest. Then we exposed the natural aggregate which comes out of our local earth.

"People tend to think of stone products from Indonesia as something that's earthy and real. And they think of concrete pavers as something fake and synthetic. So I explain to them that these products came from within 300 miles of your house. It's local dirt and it's local aggregate. It's very earthy and indigenous.

"It's a very European mentality when you look at these old French farmhouses, that the plaster came from the dirt surrounding their house. And the roof came from the clay. That's how I portray these concrete pavers as something very cool and crafted from local rock that will become a beautiful component of your house. This puts a new value on a product that's not terribly expensive."

The shot blast fee was about $1 per square foot.

Charissa had these pavers double tumbled and installed upside down in a broken joint pattern. "One of the problems with concrete pavers is the chamfer looks artificial on many products. So we installed the chamfer into the dirt.

"With a very good customized color blend, people have a hard time seeing the difference between these concrete cobbles and Indonesian granite. And it's a fraction of the price. I have multi-million dollar homes done with this. It's beautiful and very affordable."

"With a very good customized color blend, people have a hard time seeing the difference between these concrete cobbles and Indonesian granite. And it's a fraction of the price. I have multi-million dollar homes done with this. It's beautiful and very affordable."