Construction articles

Choices in porcelain colors and styles have grown with the demand for the product. Pat McCrindle says, “They're coming out with pseudo-plank material that looks like wood. There’s a product that looks just like blue stone. One that looks like travertine. There’s a product that looks like the salt and pepper granite from the Northwest. It's amazing what they're able to do with these colors.” Photo features Abbotsford Concrete’s Aristocrat porcelain.

Porcelain pavers have arrived

Porcelain pavers’ light weight, strength and beauty have taken them far in just a few years.

By Tom HatlenThe installation methods recommended in this article are the opinions of those interviewed. Because specifications for various porcelain products differ, please consult your manufacturer for installation advice on their specific products.

At HNA maybe 5 years ago there was a single small booth in a back corner marketing porcelain pavers. This year a substantial portion of the show floor will be devoted to porcelain with a multitude of exhibitors.

Contractor John McDonald started installing porcelain about 2 years ago for high-end single family homes. He says, “I get phone calls every day from people interested in porcelain. It's crazy. Now it's probably 15% - 20% of my business and growing.”

The demand has been high enough that the School for Advanced Segmental Paving brought in trainer Pat McCrindle to teach a class on porcelain installation this past winter.

Porcelain is glass

Pat says, “Basically it’s glass. So porcelain has different installation requirements. Traditionally porcelain's been an interior application. But with the new technology like the HydraPress process, the porcelain has a very high tensile and compressive strength. You can't scratch it. You can't stain it. There's really no degradation with the climate, freeze/thaw cycles, ultraviolet rays with the sun. It's just a very versatile, very resilient product that keeps its look.”Today’s porcelain paver material is so strong that standard 3/4” (20mm) thick porcelain slabs as large as 2’ x 4’ are commonly supported only by pedestals at the corners, and hold up to pedestrian traffic just fine. Some porcelain is now rated for vehicular traffic, typically mortar set on a poured concrete base.

The School for Advanced Segmental Paving held their first class on porcelain installation this last winter. Attendees learned how to install porcelain on pedestals, how to dry lay porcelain on foam panels, how to do a permeable installation, and how to do a mortar/thin set porcelain overlay on concrete.

Porcelain is laid with tools, rarely by hand. Attendees used Pave Tech vacuum tools, clamping tools and suction cups.

Porcelain is laid with tools, rarely by hand. Attendees used Pave Tech vacuum tools, clamping tools and suction cups.

Porcelain applications

Porcelain is very light, about half the weight of a comparable concrete slab. At only 9 lbs per square foot 3/4” porcelain has been very popular for rooftop applications built on pedestals.Its light weight also makes it very attractive as the surface on backyard wooden deck structures. You can do a porcelain overlay on the deck joists using the SilcaGrate system.

Pat says porcelain can be a good option for raised patios, especially those over an existing concrete slab. “Say the existing concrete slab is 600 sf 3 steps down from the back door. With 8” risers that’s 24”.

“To build a raised patio you would need to fill that 600 sf with 24” of aggregate. You're looking at well over 25 tons of material plus all the labor to get that in place and compact it. If you do a pedestal system instead, you eliminate those things.”

Pat is seeing more porcelain installations done on grade as well. “It’s being used for residential driveways, pool decks, patios, sidewalks.... I think the numbers are changing rapidly.”

Porcelain could be classified as an extremely hard glass. As such, Pat says you need a specialty saw and blade to cut it. He prefers a “bridge” tile saw (pictured) where you hold the tile in place and feed the saw into the tile. “You want to use a continuous disk diamond because a segmented diamond would cause a variegated edge and it would splinter.”

Pat says to always cut wet. “Porcelain is so hard that the blade has to spin extremely fast. The combination produces a lot of heat. The lubrication cools the blade and it also gives you a clean cut. If I was cutting dry, the heat that would generate would warp a steel blade.”

Pat says to always cut wet. “Porcelain is so hard that the blade has to spin extremely fast. The combination produces a lot of heat. The lubrication cools the blade and it also gives you a clean cut. If I was cutting dry, the heat that would generate would warp a steel blade.”

Take the plunge

Pat says taking on something new like porcelain is always a challenge. “The major issue is estimating labor for something new. We know how long it takes to lay 1,000 sf of interlocking concrete pavers. But how long does it take to lay 1,000 sf of porcelain in a random pattern on pedestals with 2’ x 2’, 2’ x 3’ and 2’ x 4’ slabs?”He says you just need to dive in. “It’s a matter of trial and error. It's getting on the manufacturer’s chat rooms and talking to the salesmen. Reps are an invaluable source to the contractor when they're trying to determine labor. Utilize those resources as much as you need to until you gain the confidence you need.”

Pat McCrindle is a regular trainer at Hardscape North America, the School for Advanced Segmental Paving and other hardscape industry events. He was a hardscape contractor for many years and is now a representative for the Abbotsford Aristocrat line of porcelain products.

All porcelain pavers are designed to be set with some type of spacer at each corner. Pat explains “While porcelain has high tensile and compressive strength, it is basically glass, and it will chip if the corners hit. Spacers keep the corners from hitting.

Spacers also eliminate the possibility of deflection with the weight of people walking on it. For many applications, manufacturers recommend using an adhesive to glue the porcelain to the spacers.

Spacers also eliminate the possibility of deflection with the weight of people walking on it. For many applications, manufacturers recommend using an adhesive to glue the porcelain to the spacers.

John McDonald says installing porcelain on pedestals takes time. “That’s because on a pedestal you have to level each one individually. It’s not like installing on grade where you just screed the entire area and lay pavers. We use levels and lasers and get everything perfect. And then, we start laying with straight edges and string lines. We like to have what we call a ‘glass finish,’ perfectly level so the corners and everything are all exactly the same height. With porcelain, you can see if they’re not level.”

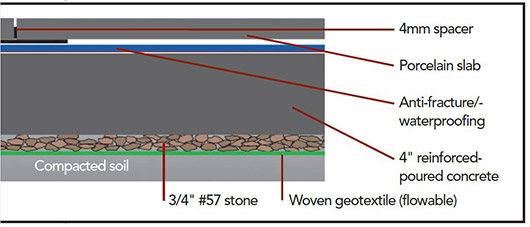

Porcelain overlay on poured concrete base

When doing a porcelain overlay on a concrete slab, Pat recommends you install an anti-fracture membrane between the porcelain and concrete. The anti-fracture membrane helps prevent cracks in the concrete from transferring to the porcelain and grout joints. Thin set mortar is then applied over the anti-fracture membrane with a trowel. “Mud” the back of the porcelain too. Using a level and rubber mallet, set the porcelain into the setting bed, wait 24 hours, and grout.

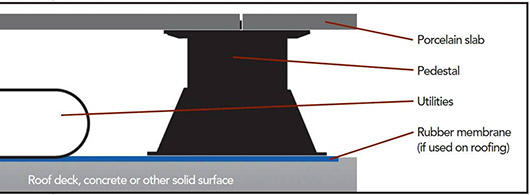

Porcelain on pedestals

Pedestals are used on rooftop porcelain patios, raised backyard patios and more. Pedestals allow you to raise the pavers from just a fraction of an inch to several feet high and compensate for an unlevel subsurface.

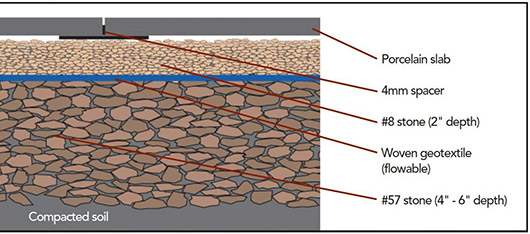

Permeable porcelain installation

The flowable non-woven fabric allows water to filtrate through while preventing the #8 stone from migrating into the #57 stone causing voids and sinkage. With a permeable porcelain installation Pat recommends not filling the joints with stone or anything else. “Like any permeable application, you may have to vacuum those joints from time to time to clear them of debris.”

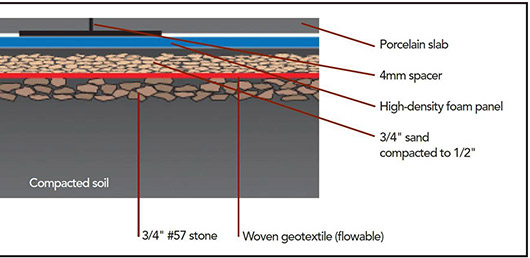

Dry laid porcelain on high-density foam panels

For dry-laid porcelain installations, Pat recommends using high-density foam panels such as Belgard EZ Base Panels, and he recommends the porcelain joints be left void. “You don’t want sand in the joints because you can’t compact a porcelain surface and force sand into the joints to create an interlock. The centrifugal force of a plate compactor may cause the porcelain to shift and the corners to chip.”

If you were to use a traditional sand-set installation – but with no sand in the joints – some of the bedding sand can migrate to the joints causing deflection and movement.

The #57 stone removes moisture to eliminate any possibility of movement with freeze-thaw cycles especially if the sub-soil has a high clay content.

If you were to use a traditional sand-set installation – but with no sand in the joints – some of the bedding sand can migrate to the joints causing deflection and movement.

The #57 stone removes moisture to eliminate any possibility of movement with freeze-thaw cycles especially if the sub-soil has a high clay content.

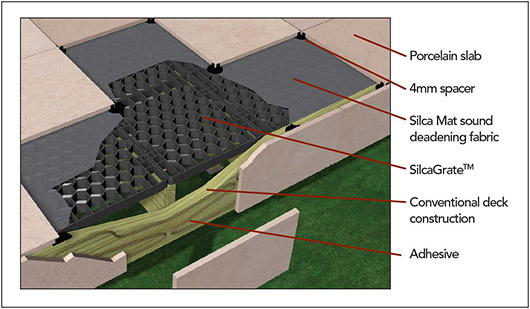

Porcelain on Silca System grate

The ICC certified Silca System lets you build a paver patio on the joists of a wooden/composite deck and other structures. “At roughly half the weight of 3/4” concrete pavers, porcelain overcomes a lot of consumer objections to weight on decks,” according to Silca System President Bart Stuchell.

Bart says leveling deck joists is critical. “Porcelain is perfect dimensionally, and when you're using those large tiles, if you've got any variance in your substructure, it will show.”

One oddity with porcelain is that it pings when you walk on it if there’s nothing beneath to deaden the sound. Bart recommends permeable Silca Mats made from recycled rubber to silence the pinging.

Bart says leveling deck joists is critical. “Porcelain is perfect dimensionally, and when you're using those large tiles, if you've got any variance in your substructure, it will show.”

One oddity with porcelain is that it pings when you walk on it if there’s nothing beneath to deaden the sound. Bart recommends permeable Silca Mats made from recycled rubber to silence the pinging.

John’s crew installs porcelain using suction cups.

Contractor tackles porcelain

John McDonald got into higher-end projects partly by taking on new things, like porcelain, and taking it upon himself to become an expert in the different application methods. As such, his competition is limited and his schedule is booked out 2 to 3 months.John started installing porcelain about 2 years ago when it first became available thru his dealer. Today it’s a profitable 15% to 20% of his business.

About 80% of John’s porcelain work has been on pedestals while the other 20% are on grade. The bulk of his clientele consists of builders and architects on upscale 10,000 to 15,000 sf homes. They hire him on behalf of homeowners.

Porcelain rooftop patios (on pedestals) are popular with his customers. “It may be that each bedroom has its own outdoor patio, as well as a larger common area with outdoor kitchens and overhead heaters. People want to maximize living space on their property so it makes sense to build upward if the outward space is limited.”

He says the square foot cost to install porcelain is nearly 2x that of installing concrete pavers, but that the customers he serves are unconcerned with that. They want the look, and they’re willing to pay for a high quality installation.

Profile

J. Mac Contracting Ltd.

North Vancouver, BCFounded 1985

John McDonald, President

Customer base

100% High-end residentialServices

90% hardscape, 10% drainageProject price range

$10,000 - $200,000Annual sales

$750,000 - $1 millionEmployees

6Installing pedestals

John says doing quality installations on pedestals is time-consuming because you have to carefully level each slab. “The nice thing about pedestals is that you can have a sloped deck and the pedestal adjustments allow you to have a dead level patio. We'll go from nothing to 2’ at times, to make it perfect.”They use pedestals to install porcelain on concrete and on roof decks. He says installing porcelain on pedestals isn’t much different than installing precast concrete slabs which he’s been doing for years. But there are differences.

“The weight of a concrete slab will hold it in place for the most part, whereas a porcelain slab is much lighter. So, you have to measure accurately and make sure it's laid extremely tight, otherwise you'll get shifting. All the edges either have to be glued or shimmed tight against the wall, or you’ll end up with irregular joints.

“Once you learn the nuances, it goes pretty easy. My guys like it because it's lightweight. I can go to a job, explain it to my crew, and leave knowing that they're going to do a bang up job because they know all the ins and outs. But, I don't leave very often.”